The new Lucas-Milhaupt® calculator makes it easy and convenient to estimate the amount of braze alloy or solder alloy required for plumbing or HVACR applications. How can you use this online tool?

- Increase accuracy of estimating the amount of alloy you need-in readily available sizes-for common tube sizes.

- The calculator conveniently determines your needed alloy volume based on the number of joints to be brazed or soldered, the maximum joint gap of standard copper tubing and fittings, and the shear depth of standard fittings, with provision for a fillet.

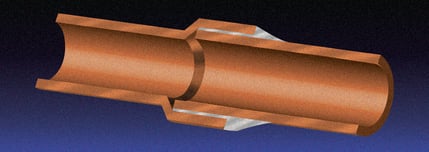

Note that your actual alloy consumption may vary based on joint size, method of application and workmanship. Use Lucas Milhaupt SilFos rings for a consistent amount of alloy consumption and joint quality for brazing copper to copper plumbing or HVACR standard tube sizes.

The Process

1. Your first input to the calculator is Tubing Type. Choose either Plumbing or HVACR.

- If you select Plumbing, the standard copper tubing sizes based on ASTM B 88 (Standard Specification for Seamless Copper Water Tube) and ASTM B 819 (Standard Specification for Seamless Copper Tube for Medical Gas Systems) appear as options for you to select.

- If you choose HVACR, the standard copper tubing sizes based on ASTM B280 (Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service) and ASTM B 837 (Standard Specification for Seamless Copper Tube for Natural Gas and Liquefied Petroleum (LP) Gas Fuel Distribution Systems) appear as your options.

2. Now, choose from the associated Tubing Sizes for your plumbing or HVACR application.

3. Filler Material-brazing and soldering alloy-is your next input. A drop-down tab lists the most common and recommended alloys for brazing or soldering copper tubing and fittings in plumbing or HVACR.

4. Then, the Wire Dimension option allows you to choose from the standard sizes offered by Lucas Milhaupt for each Filler Material option listed in the calculator.

- For example, if you select Sil-Fos® as the filler material, a list of five options allows you to choose: Round Wire (0.094 in. and 0.125 in. OD), Square Rod (0.125 x 0.125 in. cross-section), Rectangular Rod (0.125 x 0.050 in.) and OD Ring (round wire).

5. The final step in the calculator is selecting the Number of Joints you want to braze or solder.

- If you select the options of Solid Wire, Square Rod or Rectangular Rod, an output value of Length and Weight appears at right in the calculator. These outputs are the length of alloy in the form of rod or solid wire plus the weight of the filler metal needed to braze the desired number of joints input to the calculator.

- If you choose the option of OD ring (available for Sil-Fos only), an output value of Ring Size appears on the right. The data in the output Ring Size cell details the number of rings required (based on your input on number of joints), the size of the OD ring and the wire diameter used to manufacture the OD ring. Sil-Fos rings are available up to 1-1/8" OD rings for plumbing and HVACR tubing.

- The other output data cells on the right include the Minimum Tube OD, Maximum Fitting ID and the Overlap (or joint shear depth) of the copper tubing joint. These output values represent the dimensions used to determine the length, weight, and ring size needed for the specific tube sizes listed.

Try the Lucas-Milhaupt copper tubing calculator today to quickly and easily estimate materials for your next project or order. Add the page to your Favorites for fast and easy access.

References

Data from the Copper Development Association Copper Tube Handbook are listed for reference. Joint dimension data are based on ASTM specifications. Please reference Table 9 in the Copper Tube Handbook for further dimensional data.

Fitting tolerances (minimum diameter and maximum diameter) and shear depth are based on Cast Copper Alloy Solder Joint Pressure Fittings (ASME B16.18) and Wrought Copper and Copper Alloy Solder Joint Pressure Fittings (ASME B16.22).

CONCLUSION:

Ordering braze or solder alloy for joining plumbing or HVACR tubing is now easier and more accurate with the new online calculator from Lucas Milhaupt. You can efficiently estimate the length or weight of alloy needed for common tube sizes determined from the desired alloy form and number of joints to be brazed or soldered.

For more information on the variation of alloy usage and braze joint quality, see these Lucas-Milhaupt postings: Brazing with Pre-formed Rings vs. Hand-fed Rods and Comparison of Brazing Rings & Flat Rods.

We are pleased to provide expert information for Global Brazing Solutions® through our blogs and instructional videos. Feel free to share this posting with associates, and save our blog site to your Favorites for easy reference.

Questions about ordering materials for your plumbing or HVACR application? Contact us for further assistance. For detailed questions regarding specific applications, please call the Lucas-Milhaupt Technical Services Department at 800.558.3856.

Source: Copper Tube Handbook, published 2010 by Copper Development Association Inc., 260 Madison Avenue, New York, NY 10016

Disclaimer: Lucas-Milhaupt, Inc. believes the information contained herein to be reliable. However, Lucas-Milhaupt gives the technical information without charge, and the user shall use such information at its own discretion and risk. Results are calculated based on nominal values, and actual weights and dimensions may vary due to dimensional and chemical tolerance variation.