Lucas-Milhaupt performed a study on the performance of braze filler metal rings against the performance of hand-fed filler metal rods. We used three heating, ventilating, air conditioning and refrigeration (HVAC/R) industry-standard tube sizes. Five trained and certified technicians helped demonstrate the difference in joint quality when using pre-formed rings in place of hand-fed alloy.

Background

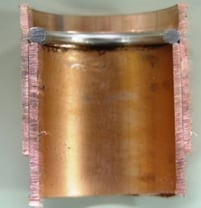

Pre-formed rings are designed to provide the correct amount of filler metal to fill a joint completely while avoiding too little-or excess-filler metal. Lucas-Milhaupt's Sil-Fos® rings designed for the HVAC/R industry provide the proper amount of filler metal for each joint. After the ring is placed inside the tube joint, as illustrated in Figure 1, the operator heats up the assembly just as during hand feeding. When the base metals are at the brazing temperature of the filler metal, the filler metal will melt and flow by capillary action along the shear depth of the joint.

Figure 1: Cross-section, pre-placed ring inside tube-to-tube joint

Figure 1: Cross-section, pre-placed ring inside tube-to-tube joint

Experiment

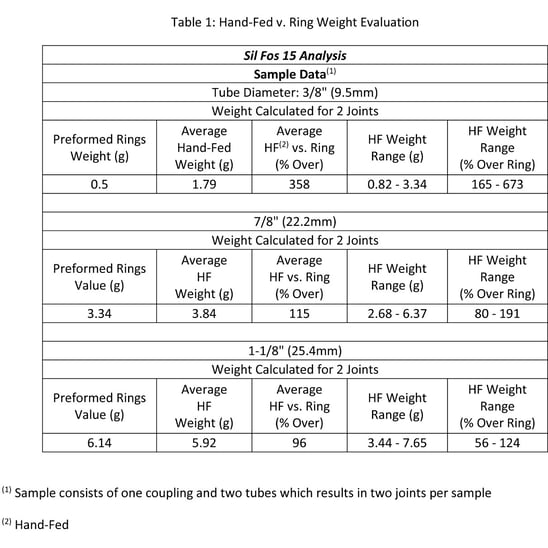

The technicians brazed three ASTM B280 and B837 standard tube size straight copper coupling joints, common to the HVAC/R industry. Each operator brazed three sizes-3/8" (9.5mm), 7/8" (22.2mm) and 1-1/8" (25.4mm)-using an oxygen-acetylene torch with the hand-feeding technique. Each part had two joints per coupling. Brazing was performed with Lucas-Milhaupt Sil-Fos 15 alloy in the rod, or stick, form with a .050" X .125" (1.3mm X 3.2mm) cross-section by 20" (50.8cm) long. See the pre-formed ring weights for these joints and the average hand-fed weight of filler metal used for each tube size in Table 1.

Results

The tube sizes brazed included the 3/8", 7/8" and 1-1/8" (9.5mm, 22.2mm, and 25.4mm) diameter sizes, using the Sil-Fos 15 filler metal. For all tube sizes, a complete exterior fillet or an exterior fillet with excess filler metal was observed before sectioning the selected parts.

3/8" (9.5mm) Tube Size:

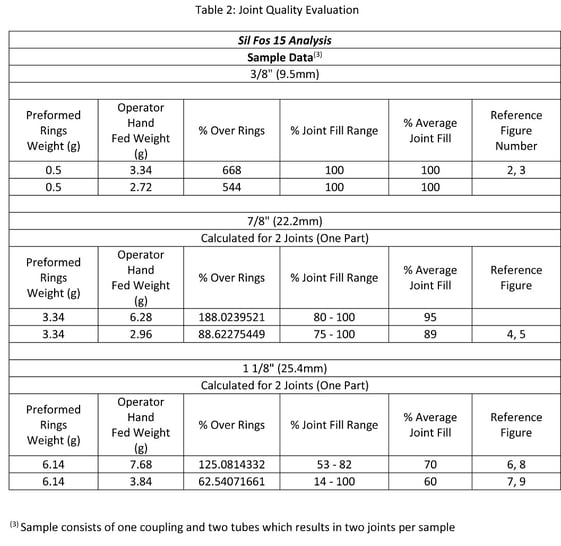

The 3/8" (9.5mm) tube size joints exhibited a complete, if not excessive, fillet on the outside of the joint, illustrated in Figure 2.

When comparing the weight of excess filler metal to the pre-formed ring weight, the hand-fed technique on average led to the use of 350% excess filler metal used in the joint. See Table 1 for this data.

Figure 2: 3/8" (9.5mm) joint overall-hand fed with rod

Figure 2: 3/8" (9.5mm) joint overall-hand fed with rod

Upon a cross-section analysis of the joint, 100% filler metal penetration was observed; this data is shown in Table 2.

However, this cross-section analysis illustrates an excess amount of filler metal, seen in the large ball of filler metal at the bottom and top of Figure 3. A proper heating method was used for this braze, but excess filler metal can be eliminated by using a preformed ring.

Figure 3: 3/8" (9.53mm) joint cross-section, internal view-hand fed with rod

7/8" (22.2mm) Tube Size:

The 7/8" (22.2mm) tube size joints also exhibited a complete outside fillet and occasional excess filler metal; this is illustrated in Figure 4.

When comparing the weight of excess filler metal to the pre-formed ring weight, the hand-fed technique on average led to the use of 115% excess filler metal used in the joint. See the data in Table 1.

Upon a cross-section analysis of the joint, a range of 75-100% filler metal penetration was observed; this data is shown in Table 2.

Figure 4: 7/8" (22.2mm) joint sectioned overall (external view)-hand fed with rod

Figure 4: 7/8" (22.2mm) joint sectioned overall (external view)-hand fed with rod

Figure 5: 7/8" (22.2mm) joint cross-sectioned void (internal view)-hand fed with rod

Figure 5: 7/8" (22.2mm) joint cross-sectioned void (internal view)-hand fed with rod

However, it should be noted that even when an average of 115% excess filler metal was used in the joint, 100% penetration was not achieved; this data can be found in Table 1. The void illustrated in Figure 5 is 25% of the shear depth of the joint.

1-1/8" (25.4mm) Tube Size:

The 1-1/8" (25.4mm) tube size joints exhibited varying amounts of excess filler metal on the tube exterior and fillet of the joint, as illustrated in Figure 6 and Figure 7.

When comparing the weight of excess filler metal used to the pre-formed ring weight, the hand-fed technique on average led to the use of 96% filler metal used in the joint. This data is shown in Table 1. However, the range in excess alloy used illustrates that less filler metal is used more frequently. The use of less filler metal could result in a lack of joint penetration when compared to the preformed ring value.

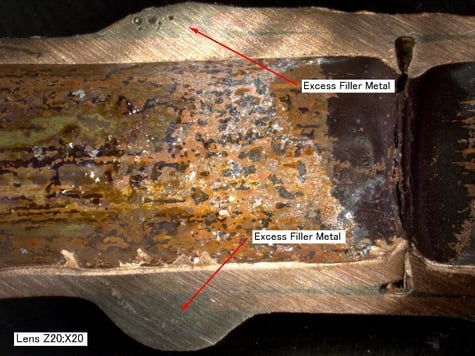

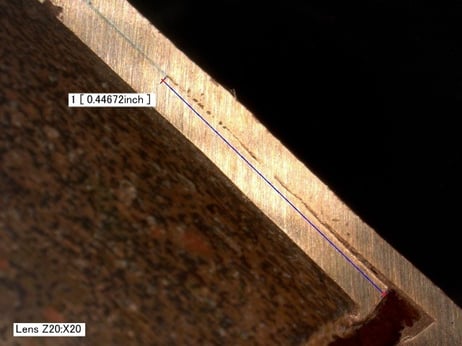

Upon a cross-section analysis of the joint in Figure 8, a range of 53 - 82% filler metal penetration was observed; this data is shown in Table 2.

Figure 6: 1-1/8" (25.4mm) joint, Tube 1 sectioned (external view)-hand fed with rod

Figure 6: 1-1/8" (25.4mm) joint, Tube 1 sectioned (external view)-hand fed with rod

Figure 7: 1-1/8" (25.4mm) Tube 2 overall (external view)-hand fed with rod

Figure 7: 1-1/8" (25.4mm) Tube 2 overall (external view)-hand fed with rod

Figure 8: 1-1/8" (25.4mm) Tube 1 cross-sectioned joint (internal view)-hand fed with rod

Figure 8: 1-1/8" (25.4mm) Tube 1 cross-sectioned joint (internal view)-hand fed with rod

When a cross-section analysis of the joint in Figure 9 was performed, a range of 14 - 100% filler metal penetration was observed; this data is also shown in Table 2.

Figure 9: 1-1/8" (25.4mm) Tube 2 cross-sectioned joint (internal view)-hand fed with rod

Figure 9: 1-1/8" (25.4mm) Tube 2 cross-sectioned joint (internal view)-hand fed with rod

The average joint penetration between these two joints is around 60% of the shear depth.

Note that even when an average of 96% filler metal was used in the joint, the average joint penetration was around 60%. This lack of filler metal penetration is shown in the gap measurements in Figures 8 and 9. One probable cause of this lack of filler metal penetration is improper heating, where the majority of the torch's flame is concentrated at the top of the joint rather than throughout the joint. This would restrict capillary action down the shear depth of the joint.

CONCLUSION:

From the data collected in this experiment, we see that pre-formed rings are more consistent in filler metal use, as well as in joint quality, than hand-fed filler metal rods. Hand-fed joints exhibited a variation of 44% of filler metal required to 670% excess filler metal used for the three different tube sizes brazed. The hand-fed joints also exhibited excessive filler metal drips on the exterior of the joints.

The variation of joint penetration observed from the hand-fed samples ranged from 14% to 100% filler metal penetration, while the joint penetration in a previous experiment using preformed rings was 100% with up to 15% voids. See this data in our blog titled Comparison of Brazing Rings & Flat Rods from June 20, 2013, on LucasMilhaupt.com: http://www.lucasmilhaupt.com/en-US/about/blog/2013/6/comparison-of-brazing-rings-flat-rod.

In summary, pre-formed rings provide a consistent amount of filler metal per joint. When heated properly, these joints exhibit complete filler metal penetration with minimum voids. Excess filler metal found on the exterior of the joints is also reduced or eliminated, providing a clean and minimal joint. At the time of brazing, this provides the operator a visual evidence of a complete internal joint. The use of pre-formed rings in the HVAC/R industry provides a leak-proof, commercially acceptable, quality joint.

Questions about Sil-Fos brazing rings? Contact us for further assistance. For detailed questions regarding specific applications, please call Lucas Milhaupt's Technical Department at 800.558.3856.

We are pleased to providing expert information for Global Brazing Solutions®. Feel free to share this posting with associates, and save our blog site to your Favorites for easy reference!