Because of tolerances, aesthetics or joint design, you sometimes need the flow of braze alloy to be restricted-to stop its flow or keep it off a surface. Capillary dams are often designed into these parts to limit braze alloy flow. A capillary dam is when the clearance is increased to a point where capillary action no longer exists. Ideal clearances for the best capillary strengths are .000"-.002" in furnace, and .002"-.005" in open air. Anything over .012" is preferred as a capillary dam. When the assembly cannot be designed to naturally prevent braze alloy flow, a brazing aid called Stop-Off can help you prevent or guide the flow of braze allow on your assembly.

Ideal clearances for the best capillary strengths are .000"-.002" in furnace, and .002"-.005" in open air. Anything over .012" is preferred as a capillary dam. When the assembly cannot be designed to naturally prevent braze alloy flow, a brazing aid called Stop-Off can help you prevent or guide the flow of braze allow on your assembly.

Stop-Off can be useful when brazing precise assembly designs involving threads or holes-where braze alloy would impede functionality. Applying Stop-Off to these areas before brazing prevents alloy from flowing to those surfaces.

Because Stop-Off stays where you place it, you can use this product to help contain the flow of braze alloy. For example:

- Some fixtures cannot be designed to avoid contact with braze joints. To prevent brazing to these fixtures, Stop-Off can be brushed onto surfaces where contact is made.

- Nonmetallic connections made after brazing, such as hoses and gaskets, benefit from Stop-Off. These regions are usually traced with a thin layer of Stop-Off to prevent braze alloy from flowing into them. This will retain the smooth finish for a hermetic seals.

Application and Adhesion

You can easily apply Stop-Off with a brush, roller or squeeze bottle. For best adhesion to your base metal surface, we recommend pre-drying to evaporate the product solvent and cure the binder at 300F for about 15 minutes depending on the size of the assembly.

Formulations

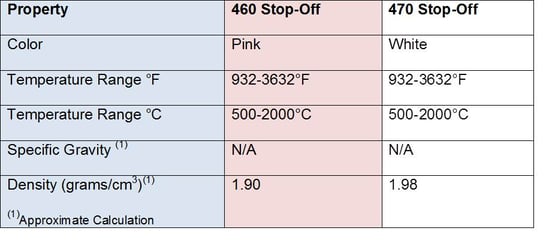

Lucas-Milhaupt offers two Stop-Off formulas. Choose the correct product for your brazing application:

- 460 Stop-Off is formulated for adhesion to base metals. Applications include dip brazing, induction, resistance applications and flame brazing with high-velocity torches. Because of excellent adherence, you may need to use mechanical post-braze cleaning methods or hot water with ultrasonic agitation.

- 470 Stop-Off is formulated for furnace and vacuum brazing. You can also use this product in torch, induction and resistance brazing. Minimal post-braze cleaning is needed, as this Stop-Off formula is reduced to a powder that easily flakes off or rinses off with hot water and minor agitation.

Adjust the viscosity of 460 or 470 Stop-Off by simply diluting the product with distilled or deionized water, isopropyl alcohol or ethanol. Be advised that diluting to excess may cause separation, but you can stir the product back to the desired consistency.

Properties

How Stop-Off Works

Lucas-Milhaupt's proprietary Al2O3 Stop-Off consists of a tenacious oxide powder in a binder system. The binder holds the oxide powder to the surface of the base metal. During the brazing process, the braze alloy will not wet the surface covered in the tenacious oxides; flux also is not able to flow between the binder and the base metal but instead has to flow over it.

CONCLUSION:

Because of tolerances, aesthetics or joint design, you may need to restrict the flow of braze alloy-to stop its flow or keep it off a surface. Examples include precise designs involving threads or holes plus specialty joints. Lucas-Milhaupt Stop-Off products provide the solution you need, with formulations 460 Stop-Off or 470 Stop-Off available to match your brazing method.

Questions? We are pleased to provide expert information for Global Brazing Solutions® through our blogs and instructional videos. Feel free to share this posting with associates, and save our blog site to your Favorites.

Contact us for further assistance. For detailed questions regarding specific applications, please call the Lucas-Milhaupt Technical Services Department at 800.558.3856.

Disclaimer: Lucas-Milhaupt, Inc. believes the information contained herein to be reliable. However, Lucas-Milhaupt gives the technical information without charge, and the user shall use such information at its own discretion and risk.