Lucas-Milhaupt has studied the use of preformed rings vs. hand-fed alloy in prefabrication of refrigeration units. Let’s look at preformed rings, the advantages of using rings, and the quality of braze joints they produce.

|

|

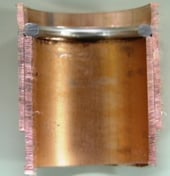

Figure 1. Cross-section, |

Preformed rings are designed to provide the correct volume of alloy to fill a joint completely, without excess material. After placing the ring inside of the joint so it is in contact with both tubes, the operator heats the assembly, just as he would with hand feeding. When the base metals are at brazing temperature, the alloy will melt, flow, and capillary through the joint to the other side.

Experiment

To demonstrate the advantages of brazing with preformed rings, Lucas-Milhaupt technicians brazed, and then compared, several samples of hand-fed assemblies and preformed ring assemblies. The components were copper, with tube-to-tube joints.

The pre-placed rings used were Lucas-Milhaupt’s Sil-Fos® (80Cu/15Ag/5P) preformed rings, called expanded-gap rings. Expanded-gap rings are oversized rings that have a gap between the two ends of the ring. This gap allows a preform to easily be placed inside of a tube and to stay in place during heating.

Process

Following are details on the experiment forming and comparing samples made with hand-fed alloy vs. assemblies made with preformed, expanded-gap rings. In the Lucas-Milhaupt test lab, two different-sized (5/8” & 7/8”) tube-to-tube joints were torch brazed with both processes:

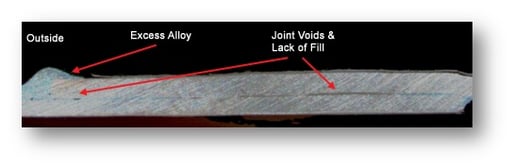

1. Hand-fed Alloy - The hand-fed samples were heated with an oxy-acetylene torch until the tubes were at uniform brazing temperature. The Sil-Fos® alloy, in rod form, was applied by hand until the joint was complete. The hand-fed joints made for both the 5/8” & 7/8” sizes appeared to be good joints with complete alloy penetration, but when they were examined, the quality was inconsistent. The joints had large fillets on the outside, but several had voids in the joint area, as shown in Figure 2, indicating quality concerns. All of the joints exhibited excess alloy on the outside, increasing the material cost of each assembly.

Figure 2. 7/8" Diameter Tube-to-tube Hand-fed Joint after Brazing

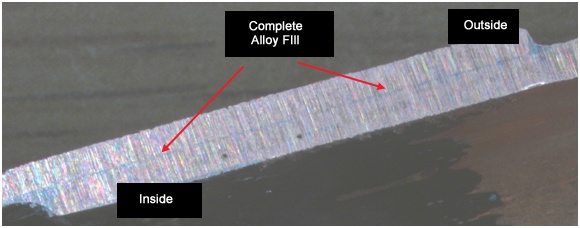

2. Preformed Rings - These copper parts were assembled prior to heating by placing the ring inside of the female tube and pushing the ring down into the joint with the male tube (see Figure 1). The tubes were then heated with an oxy-acetylene torch until the alloy flowed up to the top of the joint, indicating that the joint was complete. When examined, the joints made with the pre-placed rings showed exceptional quality, with minimal voids and little excess alloy on the exterior of the joint. Figure 3 shows an example of the complete fill seen with the expanded-gap rings.

Figure 3. 7/8" Diameter Tube-to-tube Pre-placed Ring Joint after Brazing

Results

The preformed brazing rings provided several advantages over hand feeding:

1. Improved process - the alloy was applied in the joint prior to heating, simplifying the brazing process.

2. Quality indication - when the alloy was visible at the top of the joint, operators could see that the joint was complete.

3. Consistent alloy volume - the preformed ring eliminated excess alloy on the outside of the assembly, reducing material costs and improving joint quality.

4. Fewer joint voids – the use of rings resulted in better quality, more consistent joints, reducing re-working, scrap costs, and field failures.

Conclusion

In conclusion, the brazed joints made with preformed, expanded-gap rings exhibited clear advantages over hand-fed joints. The photos in figures 1, 2, & 3 illustrate typical joint quality obtained by torch brazing and hand feeding alloy versus the quality of joints made with pre-placed rings. Preformed rings provide a higher-quality braze joint, save installers time, and reduce alloy consumption. This translates into better field performance and immediate cost savings.

To watch our rings in action, watch the video below!

Please contact us if we can be of further assistance, or if you need help with brazing products or related services.