Furnace Atmosphere

Atmosphere for furnace brazing can be a complicated issue. To understand the importance of atmosphere, let's review what we know about using furnaces as the heat source for brazing.

Furnaces can be electrically heated or fired by oxy/fuel, and they can accommodate various types of atmospheres. Furnaces are very efficient and economical in mass production environments, as they allow accurate temperature control and uniform heating of large and small parts. Plus, multiple braze joints can be completed in one operation, often without flux, and parts may not require post-braze cleaning.

Primary furnace heat transfer modes include:

- Convection - transferring and exchanging heat due to a mixing motion and movement of a fluid

- Radiation - transferring energy through a transparent medium or empty space.

Furnace types include:

- Open air - batch furnaces

- Inert/Controlled Atmosphere - retort and continuous (straight and humpback) furnaces

- Vacuum - hot- and cold-wall furnaces

Considerations for selecting a furnace process include the quantity and size of parts to be joined and the required investment in equipment. Also, the type of base metal materials and braze alloys, plus atmosphere and base metal reaction, are key.

Controlled atmospheres prevent formation of oxides and also remove or reduce oxides on the surface of base metals. This permits the filler metal to wet and flow properly to form a proper joint. Even if flux is required, a controlled atmosphere should minimize the amount needed. Remember that the brazing atmosphere you select must be compatible with both base metals and filler metals.

Active components of furnace atmosphere include:

- Hydrogen (H2) - active agent for reduction of metal oxides

- Nitrogen (N2) - displaces air/oxygen in the furnace atmosphere; excellent for copper

- Water vapor (H2O) - specified by dew point, the temperature where moisture in gas condenses; generally undesirable as it inhibits braze flow except in certain copper brazing applications

- Oxygen (O2) - undesirable result of gases absorbed on surfaces

- Inert gases - helium and argon; used in brazing metals and ceramics

Briefly, composition of atmospheres for brazing include AWS-1 through AWS-10.

- AWS-1 through AWS-4 are brazing atmospheres formed by mixtures of hydro-carbon fuel gas and air.

- AWS-5 involves anhydrous/dry ammonia with hydrogen and nitrogen.

- AWS-6 is nitrogen based with cryogenically-produced or purified nitrogen.

- AWS-7 involves deoxygenated and dried hydrogen for brazing stainless steel and alloys (jet engines).

- AWS-8 atmospheres are heated volatile materials, such as fluoride-containing hydrogen.

- AWS-9 uses purified inert gases such as argon.

- AWS-10 is a category of vacuum atmospheres involving a pumping system that lowers furnace pressure.

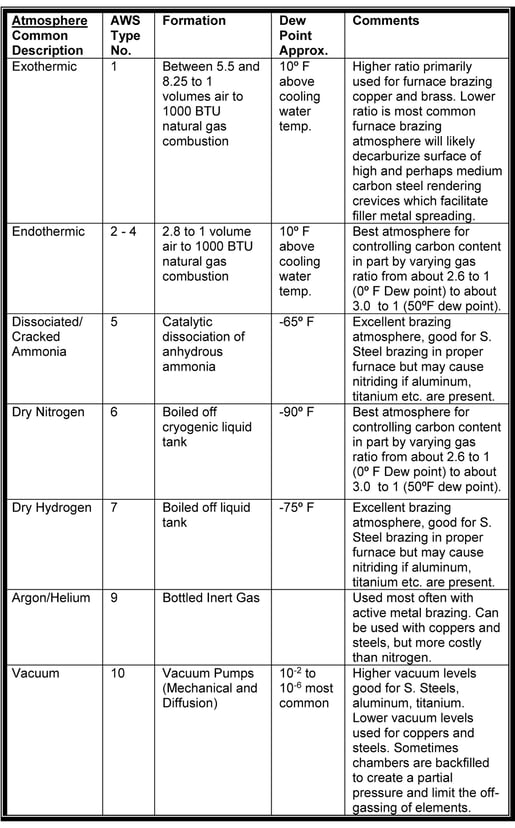

Following is a chart of atmospheres and recommended applications:

CONCLUSION:

Furnace brazing is very efficient and economical in mass production environments, providing consistent temperature and uniform heating. Multiple braze joints can be completed in one operation, with little post-braze cleaning.

Controlled atmospheres in furnace brazing prevent formation of oxides and also remove or reduce oxides on the surface of base metals. This permits the filler metal to wet and flow properly to form robust joints. Brazing atmospheres must be compatible with both base metals and filler metals.

Lucas-Milhaupt provides a complete line of braze alloys, including preforms and pastes, for furnace brazing. Please contact us for assistance with your brazing program.