Fixture Facts

A fixture is built to cradle, hold or secure an assembly to be joined. Proper fixtures should meet these criteria:

- Allow easy insertion of assembly components and easy removal of the brazed assembly

- Support assembly components to permit expansion and contraction during heating and cooling

- Support the assembly at points away from the heat zone (preventing the fixture from becoming a heat sink)

- Permit the flame to be directed around the entire joint area, so the alloy can flow throughout the joint

- Use gravity to assist capillary action

- Maintain alignment and dimensional stability until the alloy solidifies

- Be sufficiently flexible to accommodate other similar assemblies

Better Joint Design

An axiom of metal joining is that proper joint design is the path to efficient fixturing. Brazing experts at Lucas-Milhaupt offer these tips for improving your joint design:

- Make component pieces of the assembly self locating, so the fixture only supports and cradles the components.

- Allow space for the filler metal to flow and for flux to be forced out of the joint. Following is an example.

Problem: Where a tube enters a fitting or casting, some manufacturers use a press fit to keep externally applied alloy from reaching the bottom of the joint, where it might plug a hole in the fitting. Unfortunately, molten flux reaches the bottom of the blind hole and is trapped there, as alloy melts and tries to enter the joint. The alloy cannot displace the flux, so heavy flux inclusions and poor joint quality result.

Solution: Use a slip fit and a buried preform in the hole. The alloy is induced by heat to flow to the top of the joint, pushing the flux out. This leaves the hole open and results in a sound joint.

- Take into account the expansion and contraction characteristics of the metals being joined. If possible, design the joint so the higher-expansion material is the outer member of the joint. (It will expand more than the inner member, providing clearance where the filler metal will flow.)

Notes: Silver brazing is a cost-effective method for joining metals, especially when joints are designed for maximum brazing efficiency and fixtures are designed as described. Many products manufactured today could be redesigned for brazing to reduce manufacturing costs. Even though silver is expensive, it represents a small percentage of total assembly costs.

These recommendations apply to both brazing and soldering. The lower heat of soldering minimizes expansion-and-contraction problems, but the basic considerations are the same.

Fixturing Tips

Lucas-Milhaupt engineers offer these ideas for improving manufacturing efficiency with fixturing:

- Construct fixtures from 300-series, non-magnetic stainless steel for better corrosion resistance and dimensional stability (other ideas include Inconel and some ceramics).

- When fixturing for furnace brazing, hold the mass of the fixture to a minimum. (Payoff is dependent on lb/hr through the furnace; increased weight = reduced fuel efficiency.)

- When fixturing for induction heating, keep fixtures away from the work coil, so they will not act as heat sinks or interfere with the magnetic field.

- Avoid use of springs for bringing parts back to dimensional alignment. If they are required, keep them out of the heat zone, so they will not be affected by flux residue or oxidation.

- Fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. Conversion of an 8, 12 or 16 automatic turntable brazing machine stations in an hour or less should be possible. Speed changeover by using dowel pins to locate fixtures and using bolts only to secure them in place.

Examples

Examples

These examples show fixturing and joint design which result in highly efficient joining:

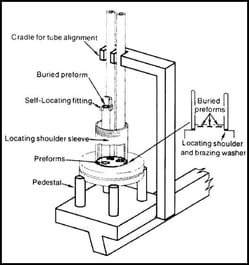

1. Single-Lever Faucet Water-Supply Assembly

This simple pedestal-fixture arrangement (Figure 1) for holding the base allows heat to be introduced into joint areas without difficulty and with minimal heat-sink effect. Components are self locating, so fixturing is very simple. The upper cradle alligns the tubes and allows them to expand and contract freely. Silver-alloy preforms in the three tube joints are buried, so when the alloy melts and flows, the parts settle from their own weight.

Figure 1 : Single-Lever Faucet Water-Supply Assembly

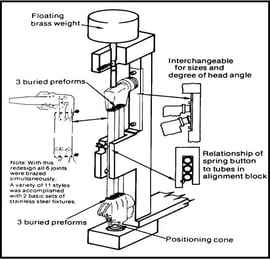

2. Family of Cutting-Torch Assemblies

Problem: In the original design, stainless tubes were pressed into the brass head and base forgings to maintain vertical alignment and eliminate flux or alloy entering the air and gas ports.

Brazing alloy and flux were applied at the top of the joint. Brazing fillets ontop gave the illusion of excellent joints, BUT alloy had not sufficiently penetrated most joints. In the field, welders use a cutting torch attachment like a hammer to break off slag, and torch producers were faced with a rash of head/tube braze failures.

Solution: Redesign the joint so the parts are of a slip-fit, self-locating type. The filler metal is buried in the bottom of the holes in the base and head. In the fixture, spring buttons and a guide block ensure vertical alignment, and the cylindrical weight allows the head and base to settle and bottom against the stainless tubes. Flux is applied automatically by three spray guns in both up and down positions

Result: With the new design (Figure 2), all six joints can be brazed simultaneously. Eleven styles are accommodated with two basic sets of stainless steel fixtures.

Figure 2: Family of Cutting-Torch Assemblies

Joints are sound, and the strengths achieved are more than 2.5x greater than with the former method.

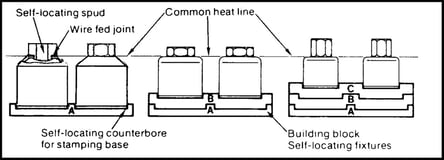

3. Family of Seven Bellows Housings

In a family of assemblies, a common denominator will allow flexibility in fixture design.Components of the bellows housing assemblies shown (see Figure 3) are brass stampings and bushings of different heights and sizes. However, joint areas to be brazed are similar on all assemblies. A self-locating, building-block fixture allows a switch from one assembly to another in minutes. The common denominator is the joint area and heat line, so the same manifold and burner arrangement accommodates seven different assemblies. This increases efficiency and decreases costs.

Conclusion

Fixture design is a key factor in achieving quality flame-brazed or soldered joints. In addition, proper joint design is the path to efficient fixturing.

Figure 3: Family of Seven Bellows Housings

Combining improvements to both these areas can result in better-quality joints, increase operating efficiency and reduce costs.

Please contact Lucas-Milhaupt with questions about fixture or joint design.

Additional resources: Lucas-Milhaupt offers consulting services, brazing audits, and engineering assistance to help overcome challenges in your operation and achieve Better Brazing.