Braze Joint Design

Lucas-Milhaupt serves a wide variety of manufacturers brazing metals. On a daily basis, we see examples of proper braze joint design that yield high-quality, strong joints and good parts. We also observe how improper design can produce weak joints, voids, and ultimately, scrap.

Improper joint clearance can impede capillary action, because only a close, uniform clearance will facilitate the drawing of alloy into a joint. If the alloy cannot completely penetrate the joint, there will be voids. Discontinuities such as voids, flux inclusions, shrinkage, and cracks all decrease joint integrity and therefore, strength. Improper joint clearance also affects hermeticity, reducing leak tightness and leading to failure.

To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature.

Do the Math

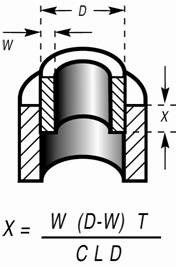

To design a braze joint and calculate the amount of filler material needed to fill the joint at temperature, consider the braze joint as a linear thermal expansion.

Change in Diametric Clearance ( DC) = (T2-T1) (D2α2-D1α1) [Eq. 1]

Where:

T1 = Room temperature

T2 = Solidus temperature of the brazing filler metal

D1 = Outside diameter of the tube at room temperature

α1 = Coefficient of thermal expansion (CTE) of the tube

D2 = Inside diameter of the fitting at room temperature

α2 = Coefficient of thermal expansion of the fitting

As an example, we will consider a 5/8" (HVAC) copper-tube-to-steel fitting joint. Using the following data:

OD of the tube: 0.622-0.626"

CTE of the copper tube: 9.8 x 10-6in/in/°F

ID of the fitting: 0.627-0.631"

CTE of the steel fitting: 6.5 x 10-6in/in/°F

Shear Depth: 0.50" minimum

What will the joint clearance be if the assembly is brazed with BrazeTM 380 (AMS 4761), which has a solidus temperature of 1200°F?

Suppose:

T1 = 68°F

T2 = 1200°F

D1 = 0.622" (Use minimum for worst case)

α1 = 9.8 x 10-6in/in/°F

D2 = 0.631" (Use maximum for worst case)

α2 = 6.5 x 10-6in/in/°F

Now, we will take these values and solve Equation 1:

ΔDC = (T1-T2) (D2α2-D1α1)

= (1200-68)°F {(0.631in) (6.5 x 10-6in/in/°F) - (0.622in) ( 9.8 x 10-6in/in/°F)}

= -0.0023"

The joint clearance calculated at room temperature is 0.0045" per side. The clearance at brazing temperature will decrease by 0.0023" diametrically, or 0.00125" radially. Therefore, the calculated clearance at brazing temperature is 0.00335". If the number were positive, there would be an increase in joint clearance.

Conclusion

It is important to design joints at braze temperature to ensure the highest quality joint. When the part is at braze temperature, if there is a reduction in joint clearance, there may be insufficient alloy penetration into the joint due to decreased volume of the joint. Likewise, if the joint clearance increases at temperature, there may not be enough alloy present, which may lead to voids in the joint. It is therefore recommended that, when joining dissimilar metals, joint clearances are calculated at braze temperature, not room temperature.

After obtaining the joint gap a temperature, we can move to the next step of calculating the appropriate volume of filler material to fill the joint. Calculating the volume will be covered in an upcoming posting.

We are pleased to provide more information on proper brazing procedures. Questions? Lucas-Milhaupt's experts can help you navigate the challenges of brazing. See the website for information on Lucas-Milhaupt products or services, or contact us.